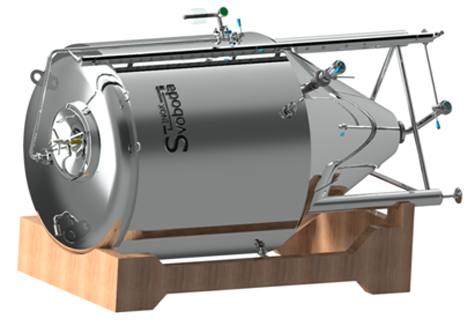

Cylindrical conical

Fermentation tank

- Fully welded outside jacket

- Adjustable legs

- Up to 3 Bar holding pressure

- Level indicator

- Manhole on the top or side jacket

- Carbonation / Oxygenation candle

- Rotation spray ball

About tank

Cylindrical-conical tank suitable for fermentation of beer, cider, kombucha, wine or other beverages. Best solution for modern way of making fermented beverage products.

Cylindrical-conical fermentation tank is stainless steel vessel mostly used for making beer, cider, kombucha, wine or other beverages. Cylindrica-conical tank know in short cut as CCT must follow all the hygienic standards, what means it must be produced from stainless steel (AISI 304 = 1.4301), must have surface finished inside at least Ra 0,8 (surface roughness) and must be equipped with sanitation CIP spray ball - watch video here. These demands will help you to keep the tank clean and prevent contamination of the next batch of beer. All brewers know that hygiene is most important part in the brewery for good quality and taste of beer. Very important is conical part what should be in 60° angle. Right angle (not very big – not too small) helps yeast sediment on the bottom. Good Brewmasters can very effectively separate yeast from the beer and get non-filtered beer in very clear condition. For this job has CCT two outlets. One for yeast on the bottom of cone and second for beer in higher position in cone (height depends on the size of tank). Standardly CC tanks are produced as pressure vessels. This means they can work under pressure from 1 – 3 Bar. 3.0 Bar tank we can call universal tank because you can use it for main fermentation, lagering and using pressure also in combination with filter, filler or other equipment in the brewery. Such a tank can replace all other types of tanks like open fermenters, lager tanks, bright beer tanks (BBT), service tanks, etc. Other accessories used on CCT are sample valve, level indicator, extra inlet for dry hopping, manometer and pressure regulator. Pressure regulator helps you to keep pressure made by yeast on required level and shows via bubbles coming out if the fermentation process works properly. Everybody knows that yeast for proper fermentation needs sugar, oxygen and right temperature. Adjusting right temperature and later regulation of it is very important and must work reliably. In this case quality CCT is equipped with two cooling jackets (duplicators), one in cylindrical part and one conical part. For best and effective cooling is important to have at least 60% of CCT covered by cooling duplicators.

Separate cooling zones help you to regulate the temperature differently if necessary – dead yeast in conus may work as kind of isolation and require different temperature. And it is natural that self-cooled tanks are isolated for saving energy and keeping environment of the fermentation cellar comfortable for movement of people. Most used isolation is PU (polyurethane foam) with thickens from 50 up to 100 mm. As most of the Breweries have sloped floor CCTs are equipped with mounting screw legs for adjusting horizontal plane.

Stainless steel tanks are not so heavy as big. Because they are empty inside and made for pressure inside not outside (very good examples is PET bottle) it very easy to damage them during transportation. For safety transport our company INOX Processing – Milan Svoboda is placing every tank on wooden pallet specially made each tank. Horizontal transport is the only way how to deliver it to breweries.

References

Our quality work is verified by maximal customer satisfaction in many European countries.

Contact us

For non-binding offer please contact us on:

Company INOX Processing – Milan Svoboda is following highest standards and norms for effective production and best quality of the products. We follow these authorities: